Offshore wind energy is at the forefront of many important discussions going on in the world today. As companies are being pushed to reduce their carbon footprint and decrease reliance on fossil fuels, wind energy is an extremely interesting option. Even though wind energy seems ideal, the actual benefits it carries in regard to sustainability are not always what they seem. One of the variables has to do with how these massive turbine constructions are protected from corrosion.

The steel foundations, the monopiles, jackets, tripods, and multi-piles all require cathodic protection. Traditionally, sacrificial aluminium anodes have been used most often. However, contrary to certain prejudices in the industry, an impressed current cathodic protection system (ICCP) does the job just as well, and with many significant advantages over aluminium anodes. Advantages which reduce both costs and carbon footprint.

CORROSION entered the Offshore Wind Industry in 2004. We took our experience and technology from other fields to create and implement ICCP systems to meet the specific needs of this sector. And we’ve been extremely successful. As the market leaders in this area, CORROSION wants to clarify and dispel misconceptions surrounding the use of ICCP in Offshore Wind.

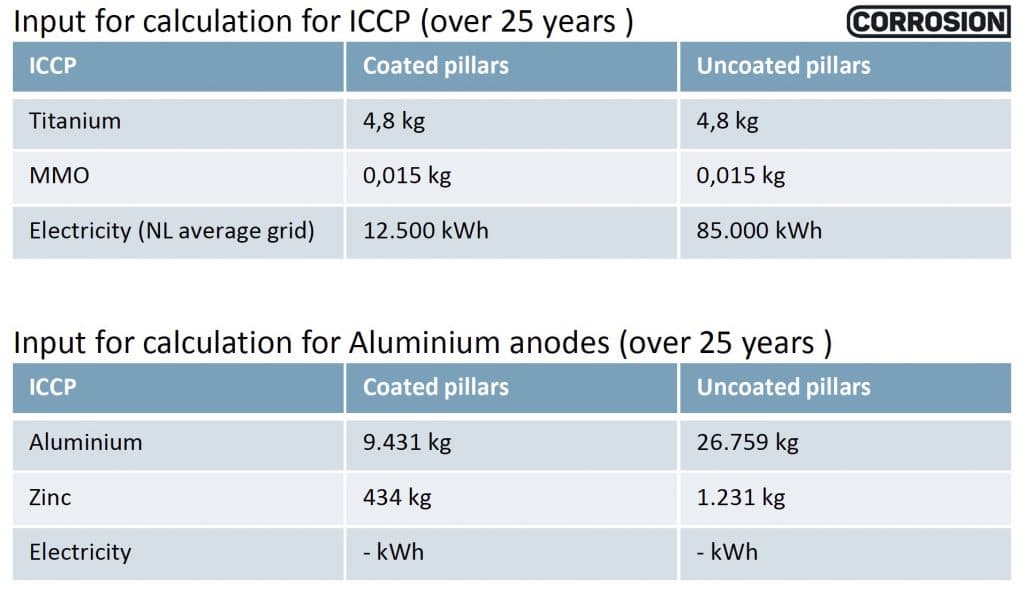

Looking at environmental impact, ICCP beats aluminium anodes in every way. The Global Warming Potential (GWP) of aluminium anodes is approximately 11 times higher than ICCP systems when it comes to coated structures and 5 times higher for uncoated structures. With regard to abiotic depletion, the impact of aluminium anodes is +/- 2300 times higher with coated structures and approximately 1000 times higher with uncoated structures.

Moreover, ICCP systems release virtually no toxic material into the environment. Sacrificial anodes, on the other hand, release enormous amounts of toxic waste as they dissolve.

ICCP is definitely greener, but it also has major advantages in relation to design, TCO, installation, and real time onshore monitoring. And, it’s more cost effective, both in the initial purchase and over the long haul. We are convinced that the pros definitely outweigh the cons.

If you’d like to know more, check out our website www.corrosion.nl, or feel free to contact us at +31 (0)79 593 1295

CORROSION: Steel Going Strong.