ICCP for floating devices

ICCP for floating offshore wind farms. Only in existence since 2017, floating offshore wind farms have huge potential as a green energy resource. Not surprisingly, just like traditional wind turbines, these ‘floating wind power plants’ of the future also need protection against the damaging and costly effects of corrosion.

CORROSION and floating offshore wind energy

At CORROSION, we are proud to support the wind sector through our pioneering Impressed Current Cathodic Protection (ICCP) systems for wind turbines monopiles.

And as the floating offshore wind turbine design evolves, so is our offering. We recently began a large-scale project with an offshore wind farm in Europe and look forward to supporting this fast-growing sector by sharing our unique knowledge and experience.

How do floating wind turbines work?

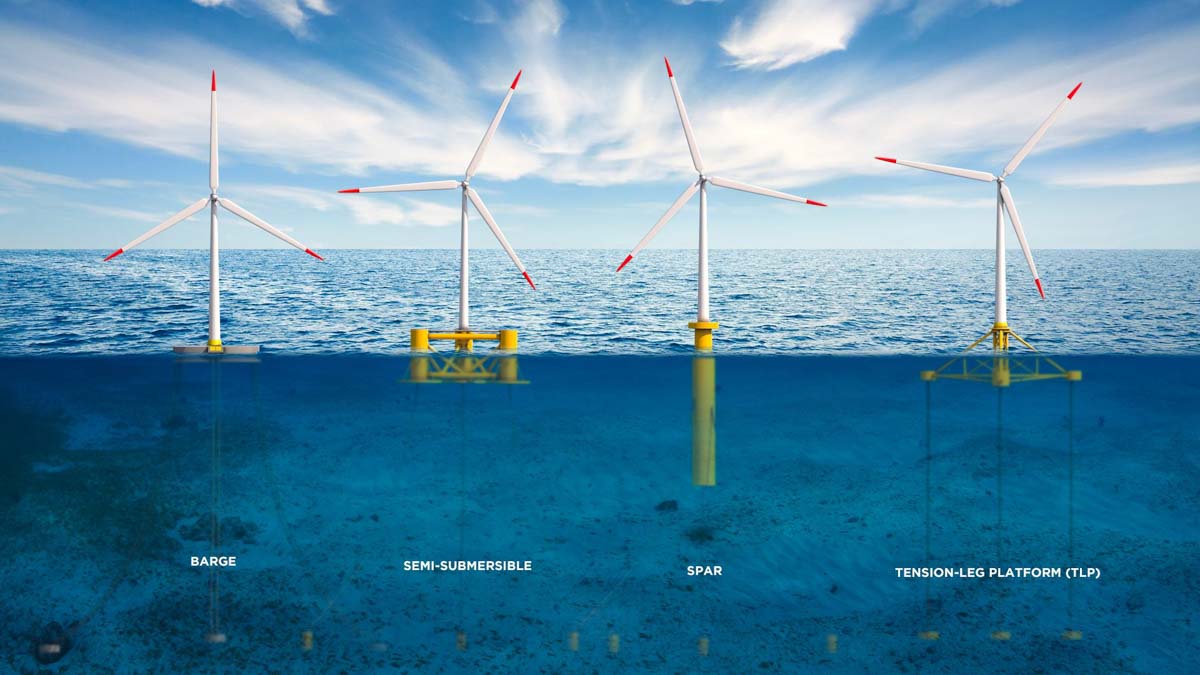

Floating offshore wind turbines consist of turbines mounted on floating offshore wind platforms. These hollow air-filled floating foundations are attached to the seabed or ocean floor to prevent them from drifting.

In contrast to fixed-bottom offshore wind turbines, which are generally deployed in water depths of less than 60 meters, a floating offshore wind turbine design can therefore be situated in waters up to 1000 meters deep.

With experts estimating that around 80 percent of the sites suitable for wind energy are in areas with a sea depth of over 60 meters, floating offshore wind farms could substantially enhance companies’ ability to harness this safe, reliable, renewable and economic source of energy.

Environmental and other benefits

CORROSION’s ICCP systems offer an environmentally friendly means to protect floating devices against the corrosive effect of sea water, as unlike traditional galvanic anode cathodic protection systems they do not lead to the leaking of millions of tons of metal alloys into the sea.

In addition, they are also highly efficient, enabling floating wind energy equipment to be monitored and controlled from a base on land.

Manager Offshore Wind

The Netherlands

“CORROSION is an internationally recognized leader in creative, sustainable, state-of-the-art solutions in corrosion and cathodic protection. Founded in 1993, one of our specialisms is the development and manufacture of products and services for the wind energy sector. Since 2008 CORROSION protected over 2.400 wind turbines worldwide and is market leader using ICCP.”

Downloads

FAQ

ICCP (Impressed Current Cathodic Protection) systems provide protection to a wide variety of vital and valuable equipment, vessels and structures onshore and offshore. Whether it’s wind turbines or tanker ships, all sorts of metal surfaces exposed to water are vulnerable to corrosion.

Offshore wind turbines are located in the seabed and floating wind turbines are mounted on a floating structure and anchored to the seabed or ocean floor. Offshore wind turbines with a fixed bottom are generally deployed in water depths of less than 60 meters, while a floating offshore wind turbine can be installed in waters up to 1000 meters deep.

Floating offshore wind turbines consist of turbines mounted on floating offshore wind platforms. These hollow air-filled floating foundations are attached to the seabed or ocean floor to prevent them from drifting.

Niels Ros

Manager Offshore Wind

The Netherlands

“CORROSION is an internationally recognized leader in creative, sustainable, state-of-the-art solutions in corrosion and cathodic protection. Founded in 1993, one of our specialisms is the development and manufacture of products and services for the wind energy sector. Since 2008 CORROSION protected over 2.400 wind turbines worldwide and is market leader using ICCP.”