Nominated – Maritime Innovation Award 2022

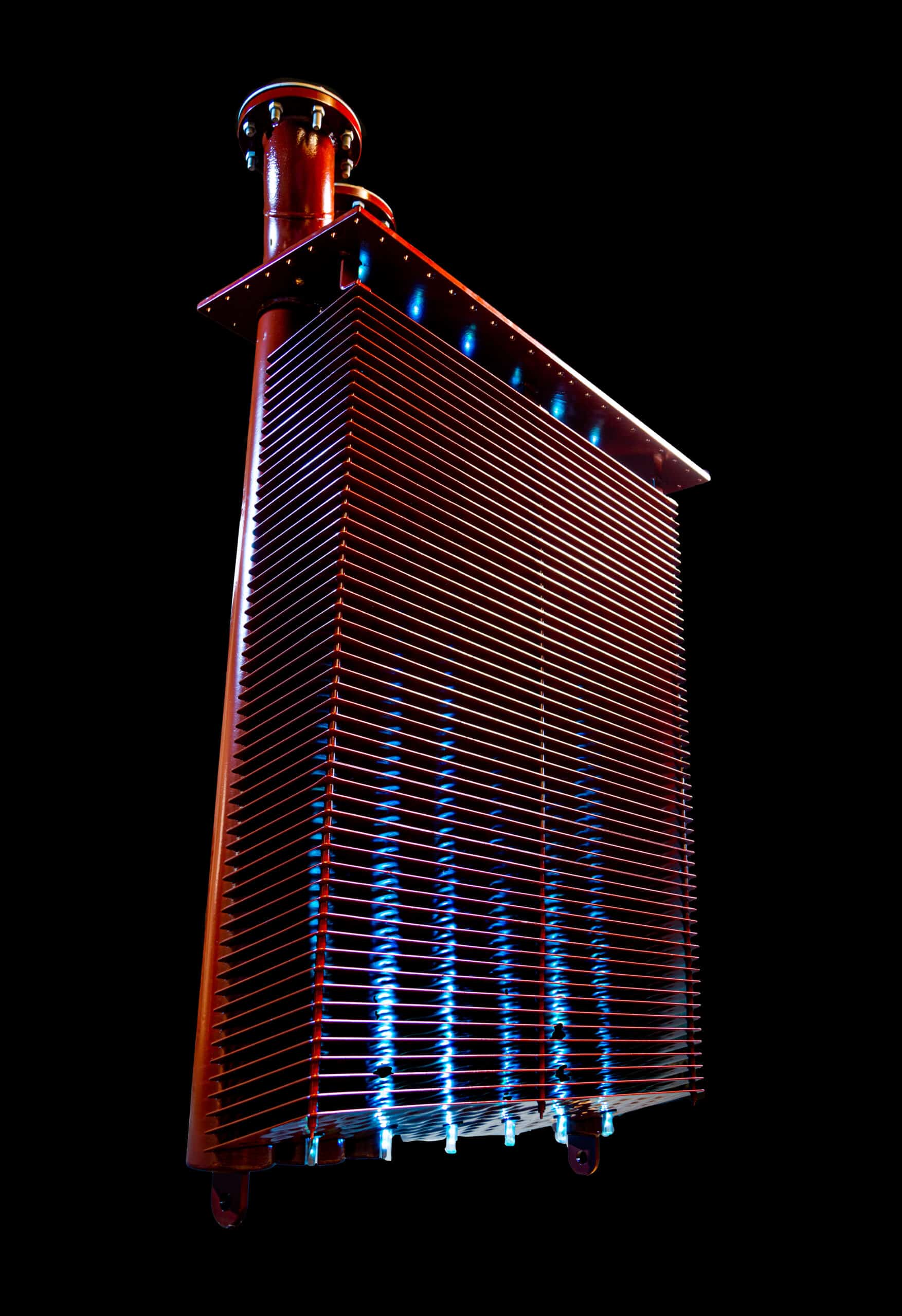

We have been nominated for the Maritime Innovation Award 2022 with our UV-C Cooler! Very proud of the recognition by our peers for years of research and hard work. Resulting in this completely Dutch and environmentally friendly anti-fouling solution. CORROSION is one of three finalists. The winner will be announced on November 7 during the Maritime Awards Gala in Rotterdam.

Press Release – CORROSION’s newly designed UV-C Cooler means goodbye to dry docking

Officially launched in July 2022, CORROSION’s newly designed sustainable UV-C Cooler is already proving highly popular with large tugboat manufacturers, dredgers and a host of other maritime customers worldwide. The revolutionary design means shipping companies can now enjoy the benefits of the cooler without having to dry dock, leading to big savings in terms of time and money.

“The launch of our updated UV-C Cooler represents a huge step forward in terms of efficiency,” said Bart Wessels, Chief Commercial Officer at CORROSION. “The new design makes it possible to replace the UV-C lamps from within the vessel by using a double enclosure rather than having to dry dock. The simple process can be undertaken in less than 20 minutes per cooler, making it quicker and more efficient than other anti-fouling solutions in the market.”

The UV-C Cooler’s newly designed coolers feature pillow-plates at an angle. This stimulates the natural convection, maintains hot spots from forming between the plates, and prevents debris and other sediment from settling on the plates.”

“What’s more, by staying clean and free from fouling, engines continue to perform at an optimum level,” added Bart. “Less CO2 is therefore released, meaning CORROSION’S UV-C Coolers are a much more sustainable and environmentally friendly solution than alternative systems.”

The newly designed cooler will be presented at the SMM exhibition in Hamburg for the first time. Interested parties are cordially invited to our stand 125 in hall A1 from September 6-9 in the Hamburg Messe. CORROSION representatives will be happy to provide further information and details regarding this exciting new design at the exhibition or through the contact information given below.

Also find the official press release here

SERVE AND PROTECT

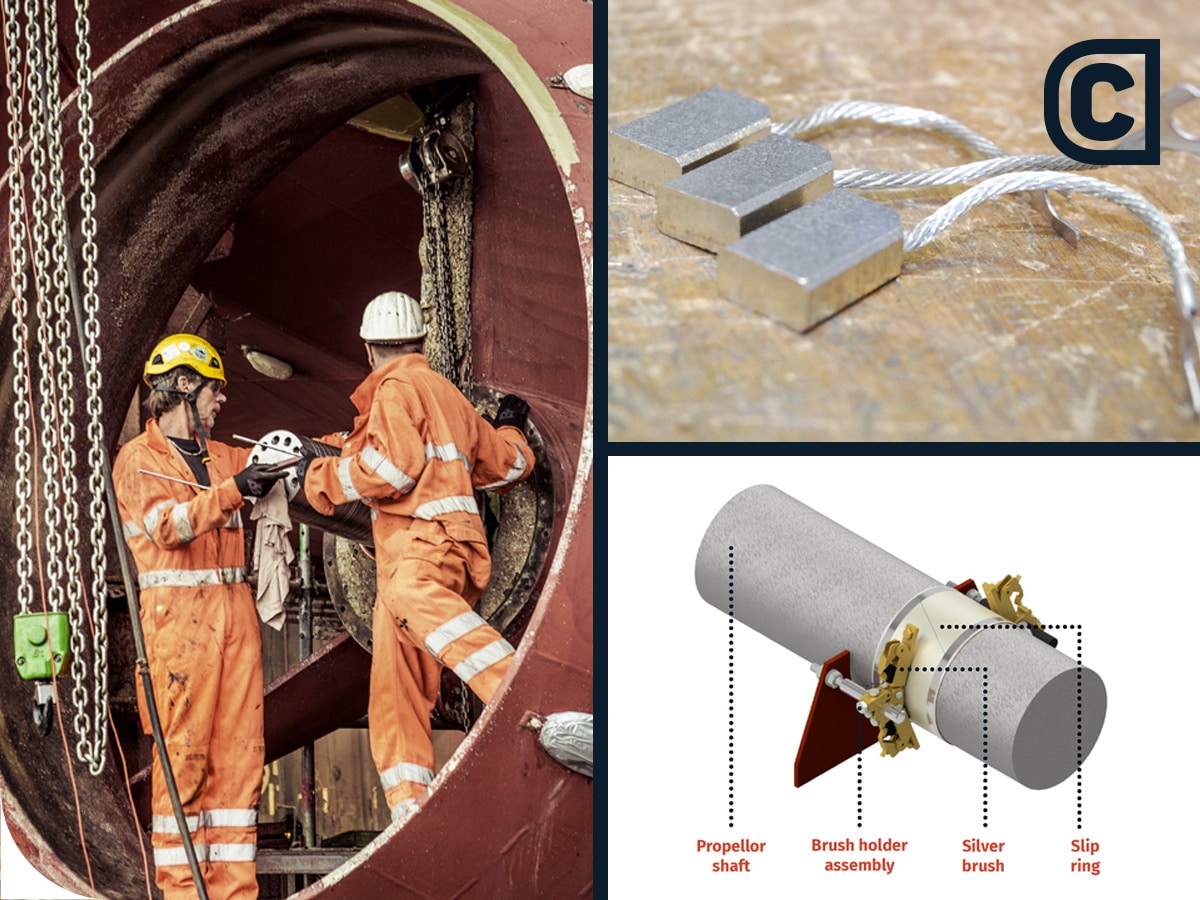

CORROSION’s R&D department, RH Marine and research institute TNO are working together on the Guarding the E-Field project. The goal of this project is to better protect the ships of the Royal Netherlands Navy against the threat of sea mines. Bureau Signaturen is the initiator of this project from the Defense Materiel Organization (DMO) – Ministerie van Defensie.

The currents running through an ICCP system produce a signal that can be detected by sensors on modern sea mines. It is therefore important to understand how an ICCP system can be deployed in such a way that the exposure to danger is as small as possible. That is why, in collaboration with TNO, a model facility has been set up at one of our locations to understand this on a small scale. After completion of the scale experiments, new technology will be brought on board the ships of our navy together with RH Marine and with the support of DMO.

We are proud to be part of this project to protect not only the ships, but ultimately their crew and their mission

Propeller Shaft Grounding

A solution to protect your vessel against spark erosion. Three question answered by Account Manager Steven Tolhoek

WHAT IS IT

The Propeller Shaft Grounding (PSG) system is installed on propeller shafts

to insure a path of low resistance.

WHY DO YOU NEED IT

To protect shaft and gearbox bearings from spark erosion created

by the difference in potential caused by cathodic protection systems.

WHY CORROSION?

We offer high silver composition brushes and include the PSG system within the Impressed Current Cathodic Protection (ICCP) system alarm and log features, which means the functioning can be closely monitored.

Read more and download our Propeller Shaft Grounding brochure here

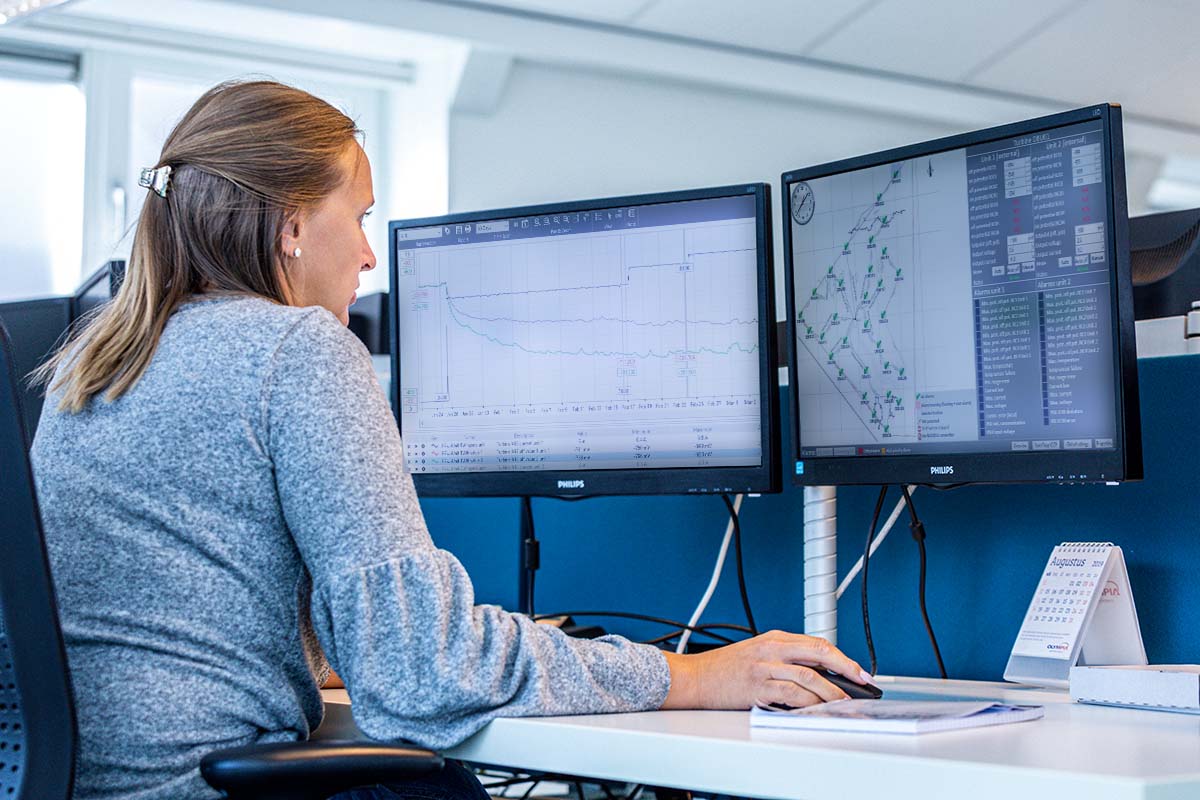

Remote management

A solution to the offshore accessibility problem with SCADA for ICCP systems. Three question answered by our Service Manager Erik Sikkel.

WHAT IS IT?

Supervisory control and data acquisition (SCADA) is a system of software and hardware elements that makes it possible to monitor and control the functionality of processes at remote locations.

WHY DO YOU NEED IT?

SCADA systems represent a highly effective solution for a range of industrial organizations as they maintain remote control and therefore the efficiency of systems, enable the processing of data for smarter decisions. And it communicates system issues to help mitigate downtime as the ICCP systems are located offshore and are difficult to visit.

WHY CORROSION?

SCADA is an essential part of ICCP systems for Offshore projects, and is specifically designed and set up according to your project’s individual design specifications.

Read more and download our new SCADA for ICCP Systems brochure here

UV-C Cooler – How Does It Work

We’re excited to introduce the first of a series of new and improved animation videos showing how our products work. Something that is not always obvious because both the operation and placement of our product often takes place below the water surface.

To meet the global demand for more sustainable solutions in the maritime sector, CORROSION’s UV-C Cooling systems offer an environmentally friendly solution for the effective cooling of engines. Without the right form of protection, these coolers soon become overgrown by marine growth, which reduces the cooling capacity of vessels’ engines.

The UVC- Coolers combine the benefits of pillow-plate-coolers with the power of UV-C lights to prevent fouling, enabling engines to function at optimum levels. CORROSION’s UV-C lighting is based on Philips’ patented IP technology. It contains energy that damages the cell structure of marine growth at the earliest stages. It only affects water flowing through the sea-chest, not damaging other organisms or leaving waste behind.

The UV-C cooler can be used for both retrofit and new building, as the cooler is custom designed to meet any specification. UV-C lights protect the Pillow Plate Coolers even during idle- AND lay-up time. A further key benefit of UV-C coolers is that the maintenance replacement process is low. UV-C lights can be replaced within just 20 minutes or less from the inside of the vessel, without even dry-docking.

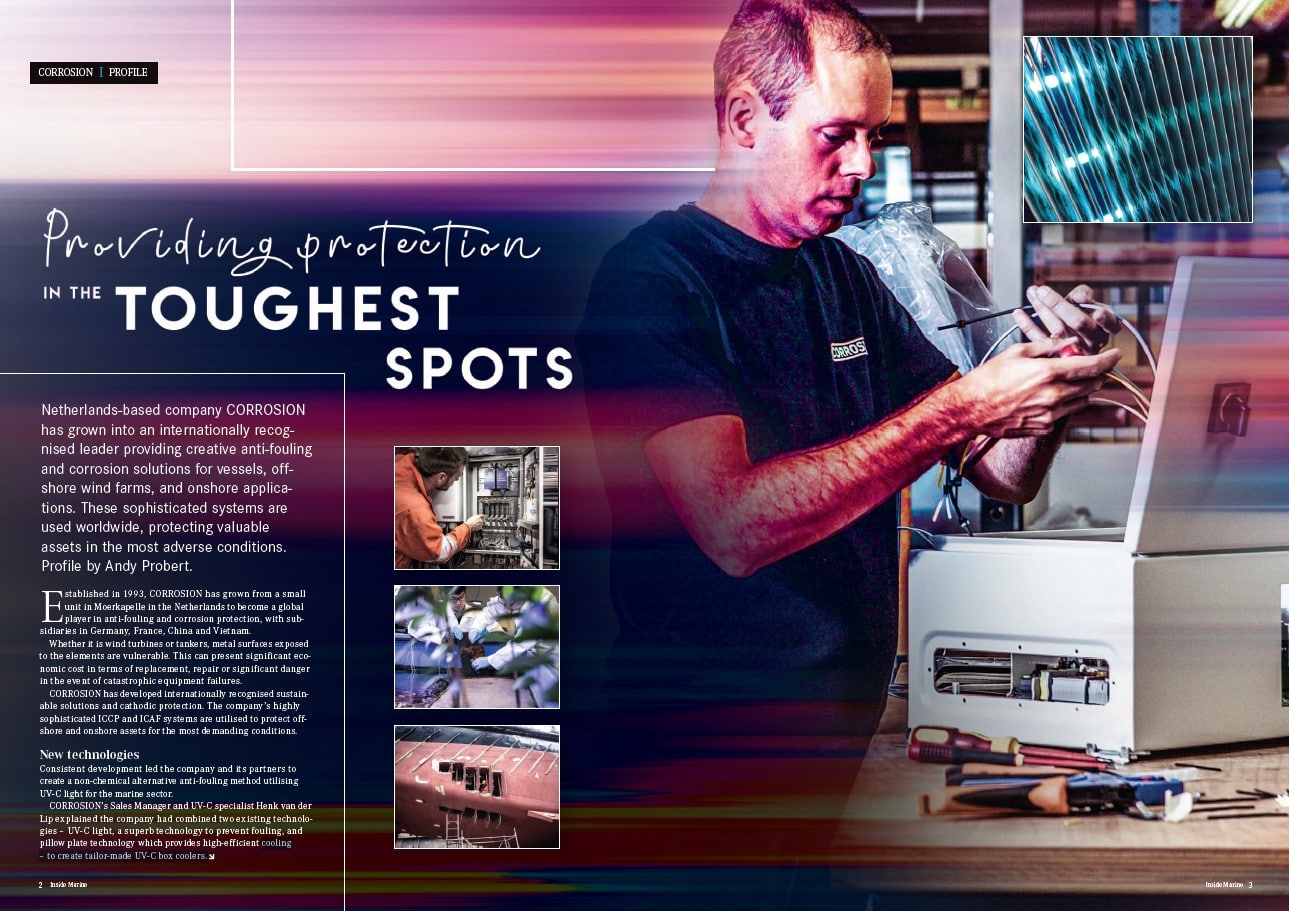

Protection in the Toughest Spots

‘Providing Protection in the Toughest Spots’ is the title of an article on CORROSION recently published in Inside Marine magazine. A profile about our company and services written by Andy Probert of Inside Marine. For this story Andy spoke with CCO Bart Wessels and Sales Manager and UV-C specialist Henk van der Lip. We think it provides an interesting and representative insight of the new technologies and sustainable innovations we are working on.

New Technologies

‘Consistent development led the company and its partners to create a non-chemical alternative anti-fouling method utilizing UV-C light for the marine sector. CORROSION’s Sales Manager and UV-C specialist Henk van der Lip explained the company had combined two existing technologies – UV-C light, a superb technology to prevent fouling, and pillow plate technology which provides high-efficient cooling –to create tailor-made UV-C box coolers.

UV-C technology provides complete environmental box cooler fouling protection, even with stagnant water in the box cooler sea chest. The UV-C uses underlying technology based on Philips IP to eliminate fouling growth. UV-C coolers can be used for both retrofit and new builds. For retrofits, the UV-C cooler is designed to be backwards compatible with the existing box cooler. On new builds, the cooler is custom-designed. “It is a proud moment for us to develop a ground-breaking system as a marine growth protection mechanism. The innovation is unlike anything on the market and fits today’s needs for sustainable solutions,” commented Mr van der Lip.’

Read the complete article here:

Editorial – Inside Marine – PDF

New old partnership

We are pleased to announce that we are also setting foot in South Korea to conquer the offshore wind market with our sustainable anti-corrosion solution.

In South Korea we enter into a partnership with well-known partner; HAEDONG METAL CO. LTD. They have been our agent in the maritime market for more than ten years. They are now going to expand their territory into the Offshore Wind market. We are very pleased that HAEDONG will now also represent our sustainable alternative to traditional protection.

The South Korean Offshore Wind market is young and eager to learn. The Korean market is open to the knowledge and experiences from Europe in the field of Offshore Wind. HAEDONG’s experience in cathodic protection is second to none. Combined with CORROSION’s expertise and our global manufacturing locations, we believe this will give us the strongest possible construction to serve the South Korean market.

Protecting Poland

We are proud to announce a new international partnership to further expand our reach and sustainable journey in the Offshore Wind and Maritime market. This time we set foot in Poland where we entered into a partnership with the men from CO-MADE. “Due to the enormous potential and developments in Offshore Wind in the Baltic States and the existing maritime repair possibilities for ships, CORROSION has decided to also collaborate with this local specialist in Poland,” says Manager Offshore Wind Niels Ros.

“The Polish offshore wind market promises enormous growth in the coming years, says Bogusz Pniewski of CO-MADE. “In 2030, a supply of 5.9 GW of green energy is expected. That calls for collaboration with experienced partners who ensure environmentally friendly technologies.”

“CO-MADE has many years of experience in project management and is very active in the offshore wind industry,” said Niels. “With the reinforcement of CO-MADE, we expect to give a boost to our sustainable ICCP system in Poland to protect foundations against corrosion. In addition, our new sustainable anti-fouling solution, the UV-C Cooler, fits perfectly into the Baltic retrofit market. Major ship owners have found the way to CORROSION to replace their existing fleet with the UV-C Cooler. We consider Poland to be a very strategic point for this product as well.”

“As forerunners in the renewable energy sector in Poland, we are creating business connections for the offshore wind and marine market,” said Bogusz. “Our team provides business matching, project management and other support to ensure quality levels within the required delivery schedule. We are very pleased to support CORROSION’s activities in Poland. The combination of CO-MADE’s knowledge of the Polish market and CORROSION’s experience as market leaders in sustainable protection against fouling and corrosion should be a successful combination.” “Successful together” and “Steel going strong” have a new meaning.”